Sejurus Yamaha NMAX “Turbo” dilancarkan di Indonesia baru-baru ini, terma “Turbo” mencetus banyak pertanyaan yang menunjukkan beberapa kekeliruan. Jadi, mari kita lihat bagaimana sebuah pengecas turbo berfungsi.

Bagaimanapun, NMAX “Turbo” tidak menggunakan pengecas turbo yang sebenar. Sebaliknya, ia adalah mod yang membuatkan transmisi CVT hasilkan tork segera untuk memecut dan memotong.

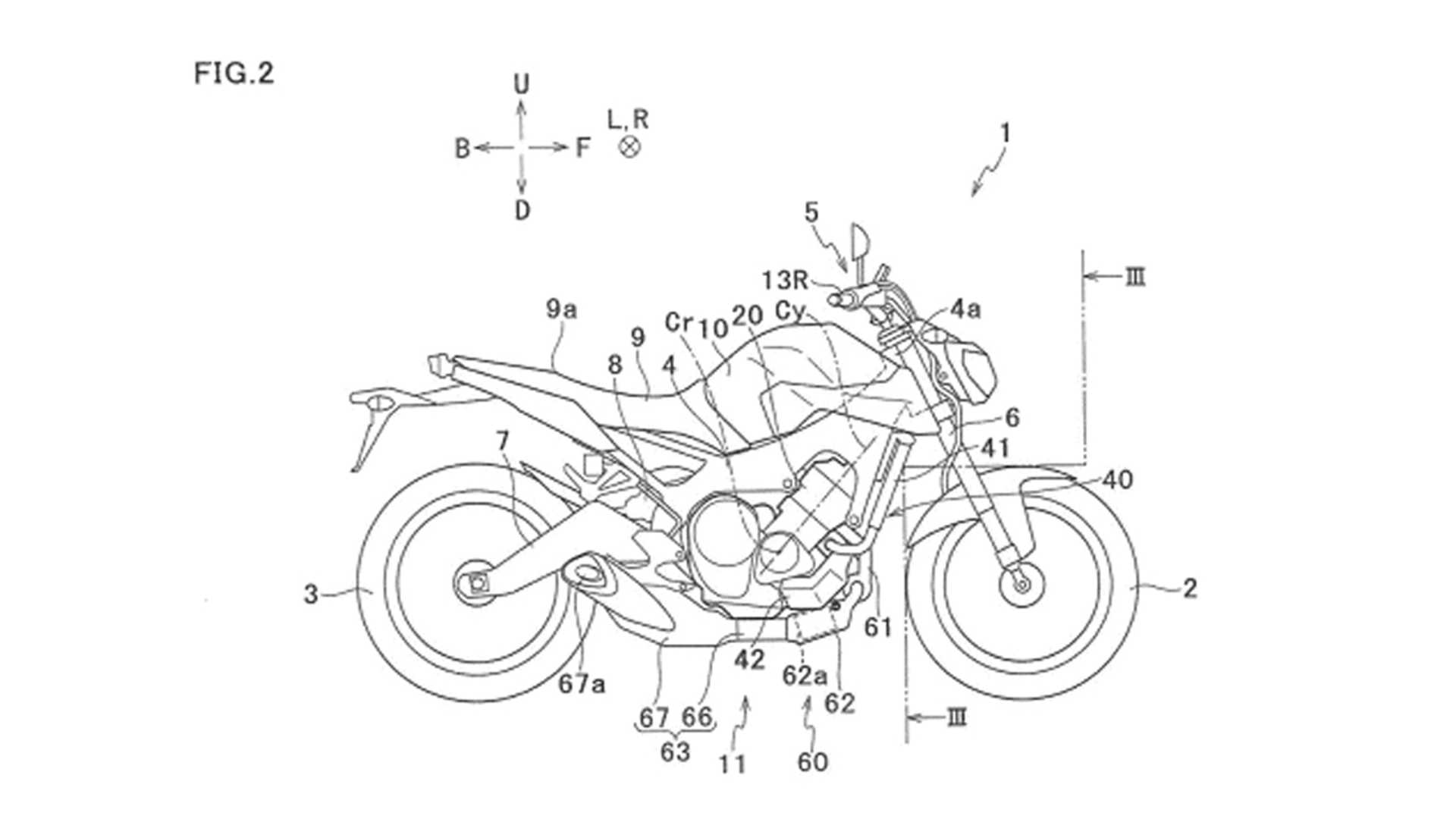

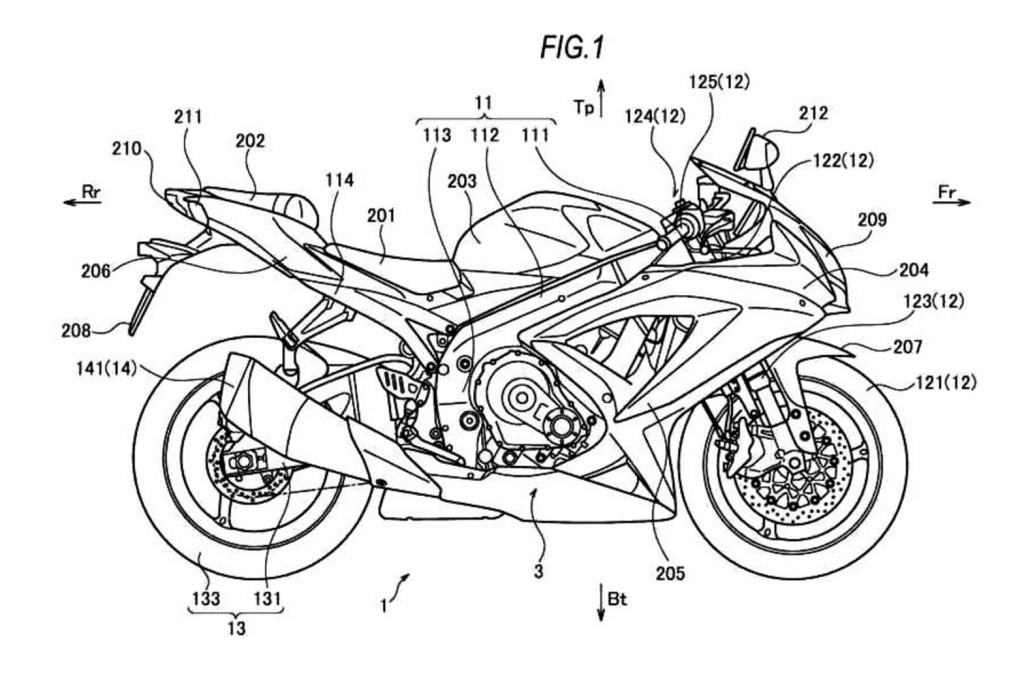

Terdapat beberapa sebab mengapa pengecas turbo tidak popular di kalangan pembuat motosikal, walaupun terdapat era motosikal yang mengunakan pengecas turbo.

Apakah turbo?

Enjin pembakaran dalaman memerlukan udara untuk berfungsi. Udara disedut masuk, dicampur dengan bahan api dan dibakar. Pembakaran ini menukar tenaga kimia dalam bahan api kepada tenaga haba, yang seterusnya menolak omboh ke bawah untuk memutarkan aci engkol (tenaga kinetik).

Walaubagaimanapun, setiap piston boleh menyedut hanya seberapa banyak udara. Udara yang tidak mencukupi bermakna anda tidak boleh mencampurkan terlalu banyak bahan api, jika tidak bahan api yang tidak terbakar akan terbuang. Oleh kerana udara dan bahan api tidak mencukupi, enjin menghasilkan tork dan kuasa yang terhad.

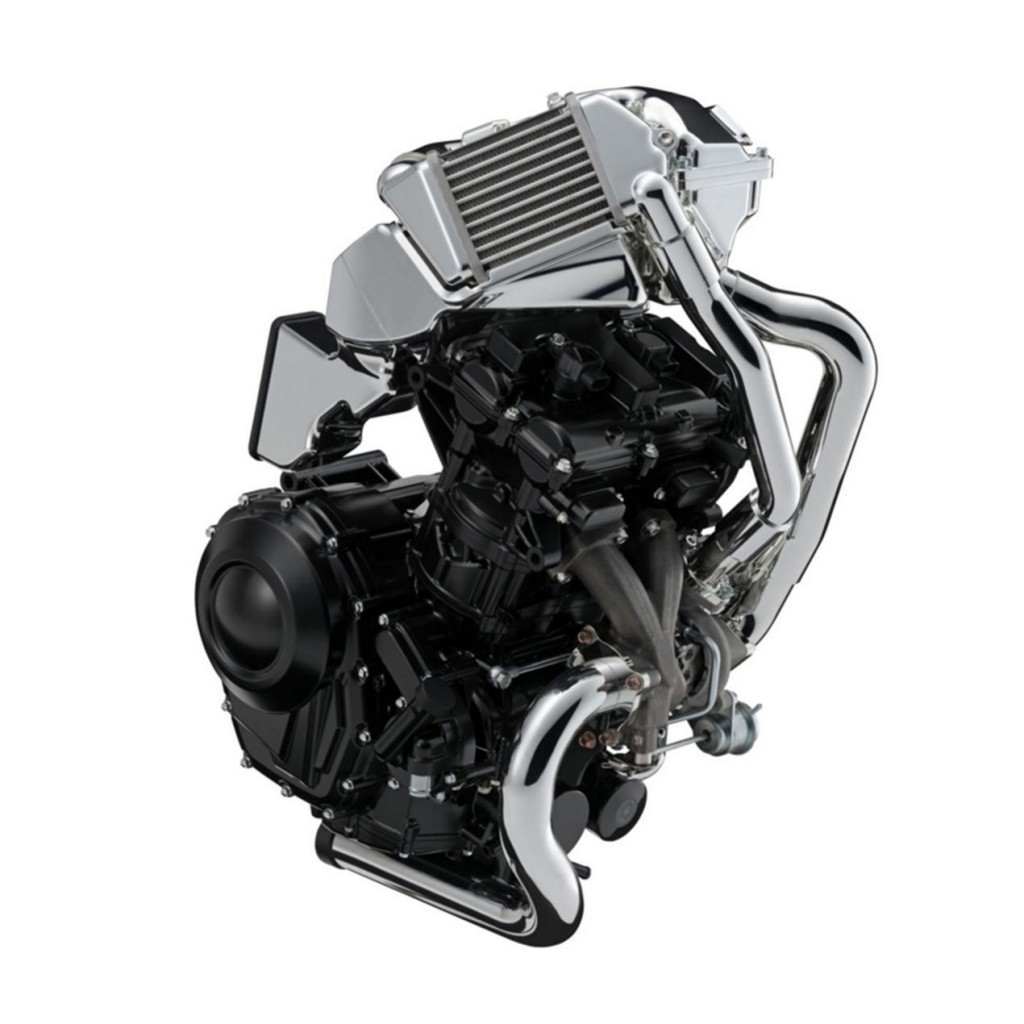

Turbo mengubahnya dengan memaksa lebih banyak udara ke dalam kebuk pembakaran, untuk dicampur dengan lebih banyak bahan api, jadi enjin boleh menghasilkan lebih kuasa lebih tinggi.

Bagaimanakah ia berfungsi?

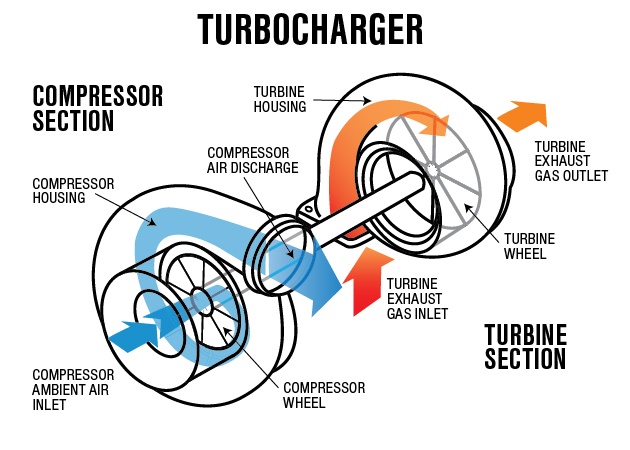

Premis asasnya ialah pengecas turbo menggunakan gas ekzos (daripada dibuang terus) untuk memampatkan udara.

Secara spesifik, pemampat dalam pengecas turbo menekan udara masuk sebelum ia memasuki manifold kemasukan udara.

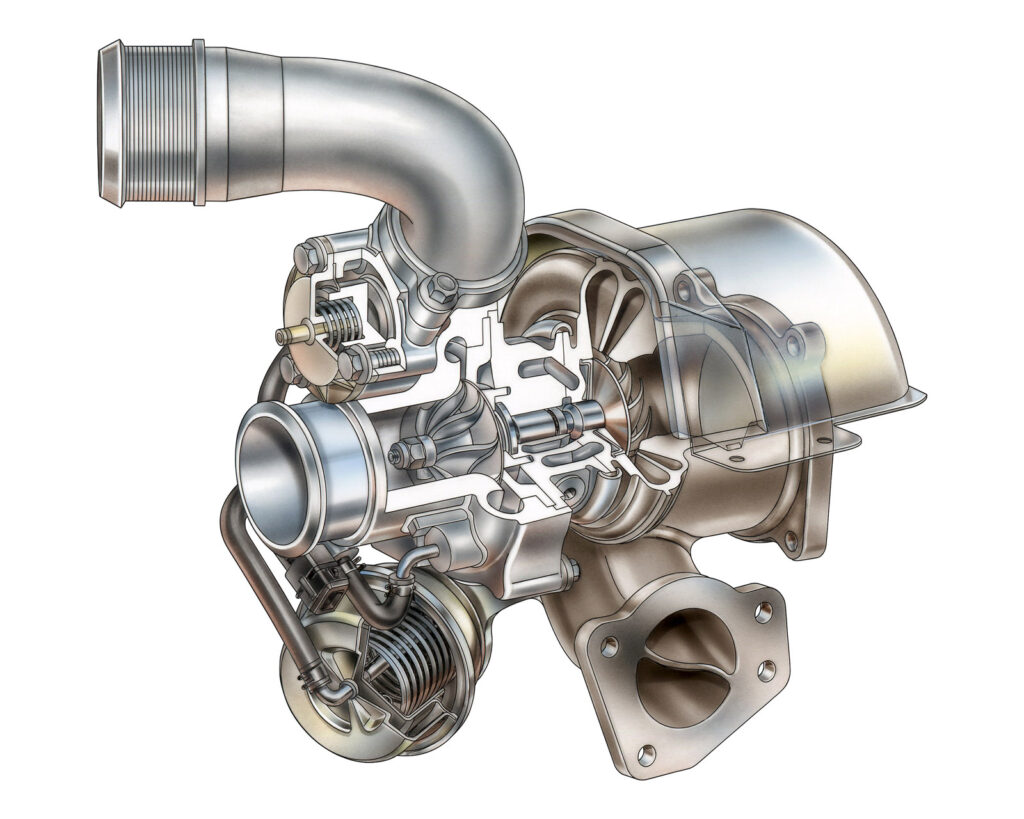

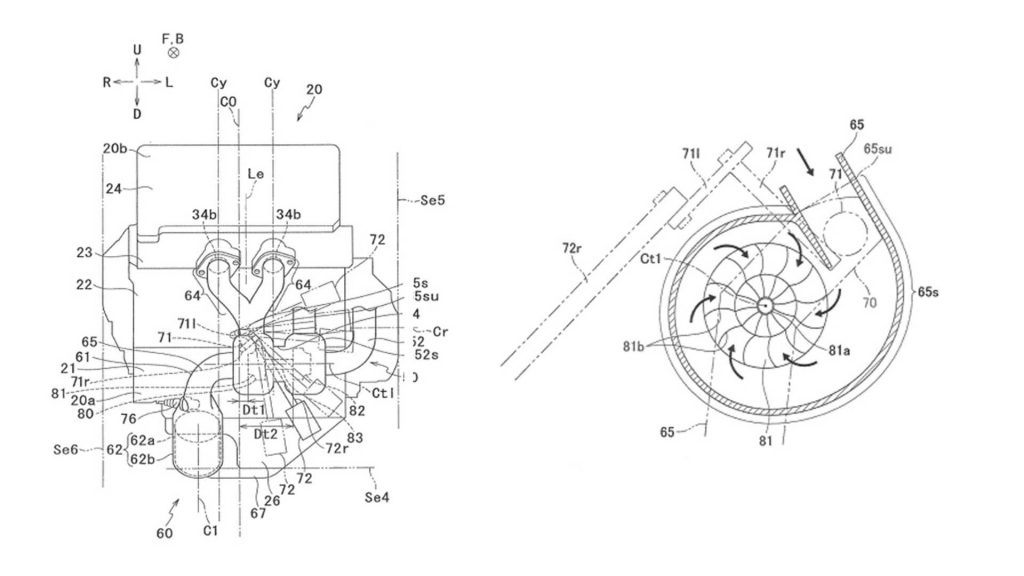

- Komponen utama pengecas turbo ialah:

- Turbin – biasanya dengan rekabentuk jejari.

- Pemampat – biasanya jenis pemampat emparan.

- Hab aci pusat berputar.

- Turbin

Bahagian turbin (juga dipanggil “bahagian panas” atau “bahagian ekzos” turbo) ialah tempat daya putaran dihasilkan, untuk turut memutarkan pemampat (melalui aci berputar melalui tengah turbo). Selepas ekzos memutarkan turbin ia terus masuk ke dalam ekzos.

Turbin menggunakan satu siri bilah untuk menukar tenaga kinetik daripada aliran gas ekzos kepada tenaga mekanikal aci berputar (yang digunakan untuk menggerakkan bahagian pemampat). Perumah turbin mengarahkan aliran gas melalui bahagian turbin, dan turbin itu sendiri boleh berputar pada kelajuan sehingga 250,000 rpm.

- Pemampat

Pemampat menarik udara luar melalui sistem pengambilan udara dan memampatkannya, dan memaksanya ke dalam ruang pembakaran (melalui manifold masuk).

- Hab aci pusat berputar

Hab aci pusat berputar menempatkan aci yang menyambungkan turbin ke pemampat. Aci yang lebih ringan boleh membantu mengurangkan kelambatan galakan turbo (turbo lag). Bahagian juga mengandungi galas untuk membolehkan aci ini berputar pada kelajuan tinggi dengan geseran yang minimum.

Sesetengah hab disejukkan dengan air dan mempunyai paip untuk mengalirkan coolant enjin. Satu sebab untuk penyejukan air adalah untuk melindungi minyak pelincir pengecas turbo daripada menjadi terlalu panas.

Keburukan pengecas turbo

Setiap penyelesaian kejuruteraan mencipta masalah lain. Begitu juga dengan pengecas turbo, maka penggunaannya terhad.

Kelewatan galakan turbo

Kelewatan galakan turbo atau turbo lag merujuk kepada kelewatan yang berlaku antara menekan pendikit dan pengecas turbo untuk memberikan tekanan rangsangan. Kelewatan ini disebabkan oleh peningkatan aliran gas ekzos (selepas pendikit dibuka secara tiba-tiba) mengambil masa untuk memutarkan turbin ke kelajuan di mana rangsangan dihasilkan (disebabkan oleh inersia turbin). Kesan kelewatan galakan turbo melambatkan tindak balas pendikit, justeru melambatkan penghantaran kuasa.

Kemudian, apabila tekanan rangsangan mencukupi, tork enjin meningkat secara tiba-tiba dan menyebabkan kenderaan memecut dengan tiba-tiba yang boleh mengejutkan penunggang.

Terdapat cara untuk mengatasi kelambatan ini,tetapi ia memerlukan banyak teknologi dan menjadi mahal.

Haba

Sistem turbo menjana banyak haba, memerlukan penggunaan minyak yang boleh menahan penyeksaan. Oleh itu, hanya minyak enjin sintetik disyorkan.