-

The OEM rubber brakes hoses typically need to be replaced every four years.

-

You can choose to replace them with braided steel lines.

-

Steel lines are more durable.

As we mentioned previously in other articles about brakes, brake hoses are considered consumables, that is, they need to be replaced some time down the road. The question then is to whether replace them with OEM rubber hoses or braided steel lines?

Before we go further, let us explain that most top-of-the-line motorcycle models are already equipped with braided steel hoses, especially sportbikes. As for those in other segments, there are manufacturers who include them as OEM from the factory, while those of the lower categories may not.

So, let’s assume that your bike is fitted with rubber hoses. Rubber brake hoses need to be replaced every four to six years, depending on your manufacturer’s recommendations.

OEM rubber hoses deteriorate over time

Over time, the rubber becomes soft and will expand when subjected to the high stresses of the brake system. Consequently, you lose braking power. In other words, some of the brake fluid’s pressure’s lost in pushing brake hose outwards, instead of being concentrated on the caliper(s) pistons.

The lever will feel spongy and you lose feel of how much you can taper off the pressure on the lever. This is especially irritating when you need to trail brake into corners – the brake seems to just let go. When that happens, the forks will rebound abruptly therefore shifting the bike’s weight to the back. This will cause the bike to run wide or even overshoot the corner.

What’s the difference between rubber hoses and steel braided lines?

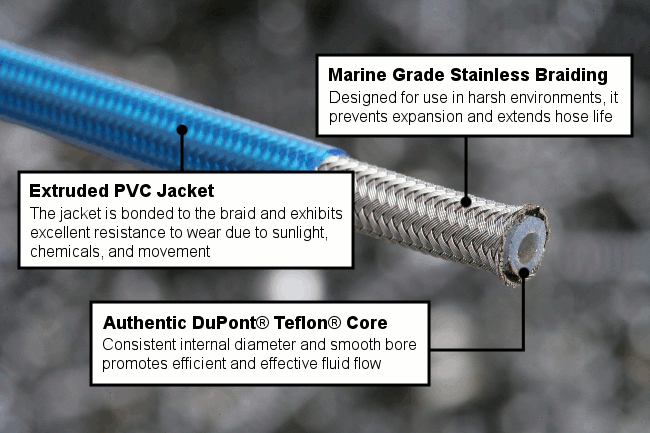

In a steel braided line, a steel casing surrounds the core hose inside, made of either nylon or Teflon. A PVC protective layer covers the steel line. It’s best to choose the PTFE Teflon core as it can resist much higher temperatures generated during braking.

The steel casing keeps the inner hose from expanding when the brake is applied. As a result, you have a better feel of how much braking you can apply, rather than relying on just the feel of the bike’s speed alone. This is especially helpful when you need to trail brake or letting off some pressure to enable you to steer the bike.

What you shouldn’t expect after switching to steel braided lines

Don’t expect your bike to brake like Marquez’s bike for Turn 9 at the Sepang International Circuit. Braided lines give you better feel and return some of your brake’s power, but you won’t get eye-popping braking all of a sudden.

What to look out for

If you end up getting a steel line with a smaller inner diameter compared to your OEM hoses, do expect that the brake lever will require slightly more travel. This is due to the increase of pressure in the line due to the smaller orifice, as stated in Bernoulli’s Principle. As such, the brake master pump’s cylinder needs to travel a little further.

But more critically, do look for quality steel lines rather than some el cheapo ones. Never compromise on quality when it comes to brakes. Besides, good braided steel lines could last for a long time.