The 2025 MODA Sporter-S was launched on 2 January, with the distinction of being a locally-made 250cc sport scooter.

From the press release:

Mdua Motor Sdn. Bhd., a subsidiary of AFY Mobility Industries (AMI) today launched a new local motorcycle brand MODA, which focuses on marketing scooter products to the entire Malaysian market. Also launched at the event today was the MODA Sporter-S which is powered by a 250cc engine.

The introduction of this scooter model by MODA is in line with the rapid development of the scooter segment in Malaysia. There is no doubt that scooters are now becoming the main choice due to their diverse functions, affordability, and practicality in urban areas. In countries such as Indonesia, Thailand, and Vietnam, scooters have already dominated the market by controlling more than 70% of total motorcycle sales.

In Malaysia, scooter sales and market are also increasing as it is driven by awareness of the need for fuel-efficient and more environmentally friendly vehicles. The scooter market is directly expected to generate a total revenue of US$0.51 billion in 2024 and grow at a CAGR of 3.98% to reach US$0.62 billion by 2029.

The introduction of the MODA Sporter-S has indirectly opened up a new segment with a design inspired by sportsbikes that features a more aerodynamic and bold design. As is well known, currently most scooters in the Malaysian market mostly feature sporty and unique designs like this, which will certainly attract the interest of motor sports enthusiasts in Malaysia.

The Sporter-S is also equipped with advanced safety features with the characteristics of a sportsbike. Among them are twin disc brakes at the front combined with a dual-channel ABS system (front and rear) equipped with 4-piston caliper brakes for more precise braking force. The Traction Control System (TCS) technology on the Sporter-S also ensures stability when cornering on challenging surfaces.

In addition, this scooter also has a fuel tank with a capacity of 13 liters, which is sustainable for long trips. In addition, the storage space under the seat can accommodate two full-size helmets, providing additional convenience for daily riders. Interestingly, it is also equipped with several interesting features such as an ultra-bright LED Matrix headlight, smart key, wireless connection between mobile devices and a large 6.2-inch TFT color screen that supports calls and full navigation while riding.

Overall, with the offering of a 250cc scooter that generates 24.8hp of power, it is enough to be categorized as one of the best and most powerful scooters in its class.

According to Micheal Yeoh, Assistant General Manager of Mdua Motor Sdn. Bhd., the MODA Sporter-S has been designed and developed with the principle of ‘By Bikers, For Bikers’ in mind. He added that the Sporter-S will be the ideal choice for bikers in Malaysia with its sporty, aerodynamic design, and features such as ABS braking system and Euro-4-spec engine that is fuel-efficient.

Offered in two attractive colours, Sporty Red and Meteor Grey, the Sporter-S is now available at MODA authorised dealers nationwide. For more information, visit the official website at www.modamotorcycles.com.

Specification:

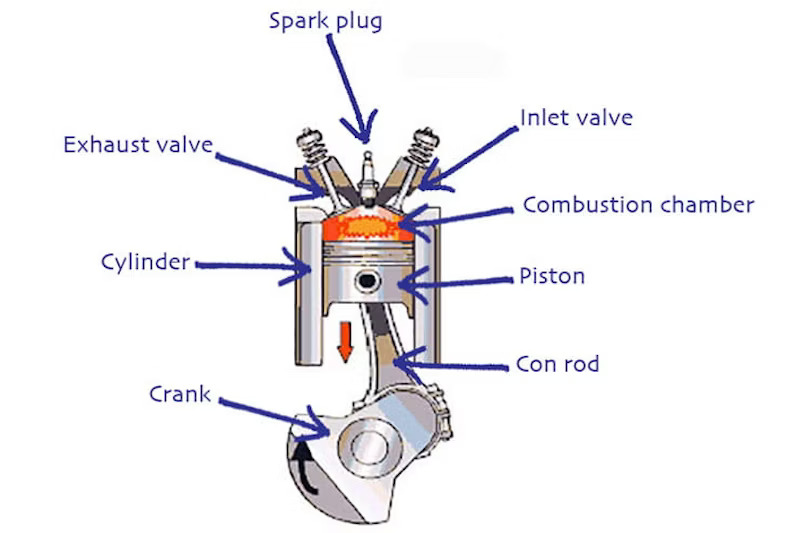

- 4-Valve, 1-Cylinder, SOHC Engine

- Electronic Fuel Injection System (BOSCH EFI)

- Electronic Engine Management (BOSCH)

- Electric Starter

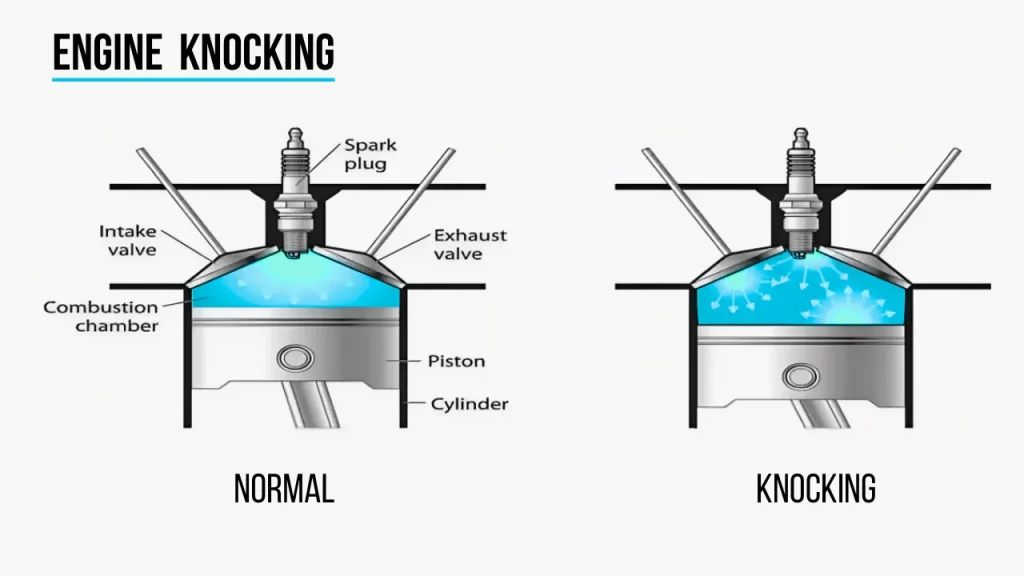

- Full Transistor Ignition

- CVT Transmission

- Euro 4 Certification

- Engine Capacity 244cc

- Maximum Power 24.8 Hp @ 8500 rpm

- Maximum Torque 22.5 Nm @ 6500 rpm

- Liquid Cooling System (Panasonic Radiator)

- Front Brake ABS 260mm Dual Floating Disc

- Rear Brake ABS 240mm Single Disc

- Front Suspension Inverted Fork

- Rear Suspension Adjustable Shock Absorber

- Smart Key Lock System (Wireless)

- Wheelbase 1538 mm

- Minimum Ground Clearance 165 mm

- Weight 186 Kg

- Tank Capacity 13 Liters