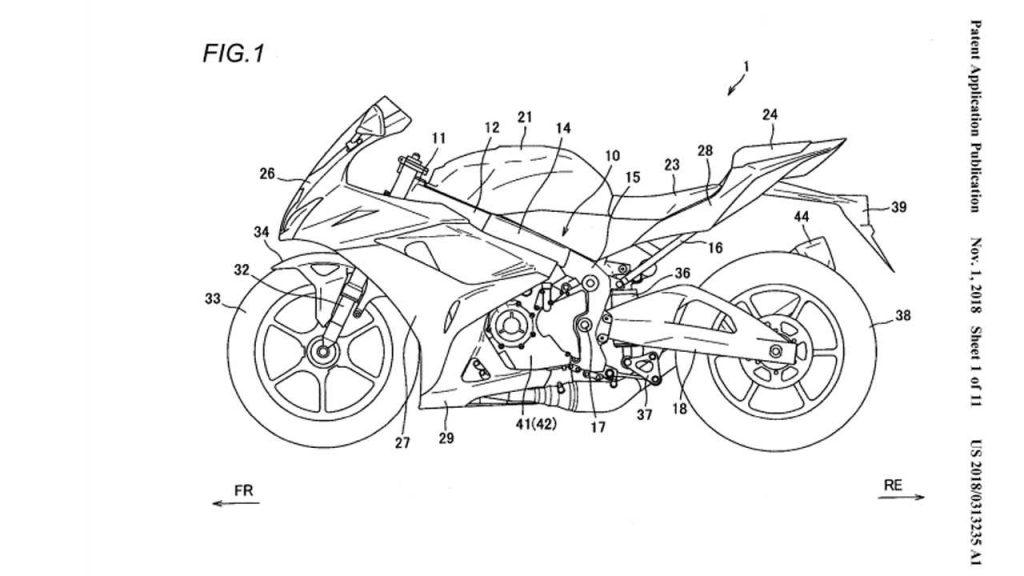

VVT and variable valve lift (VVL) are not a new technologies as many manufacturers are already employing it in their products, but Suzuki’s system appears to be for a 250cc engine. This bodes well as there are either large capacity and small capacitiy motorcycles employing it but not the 250cc segment.

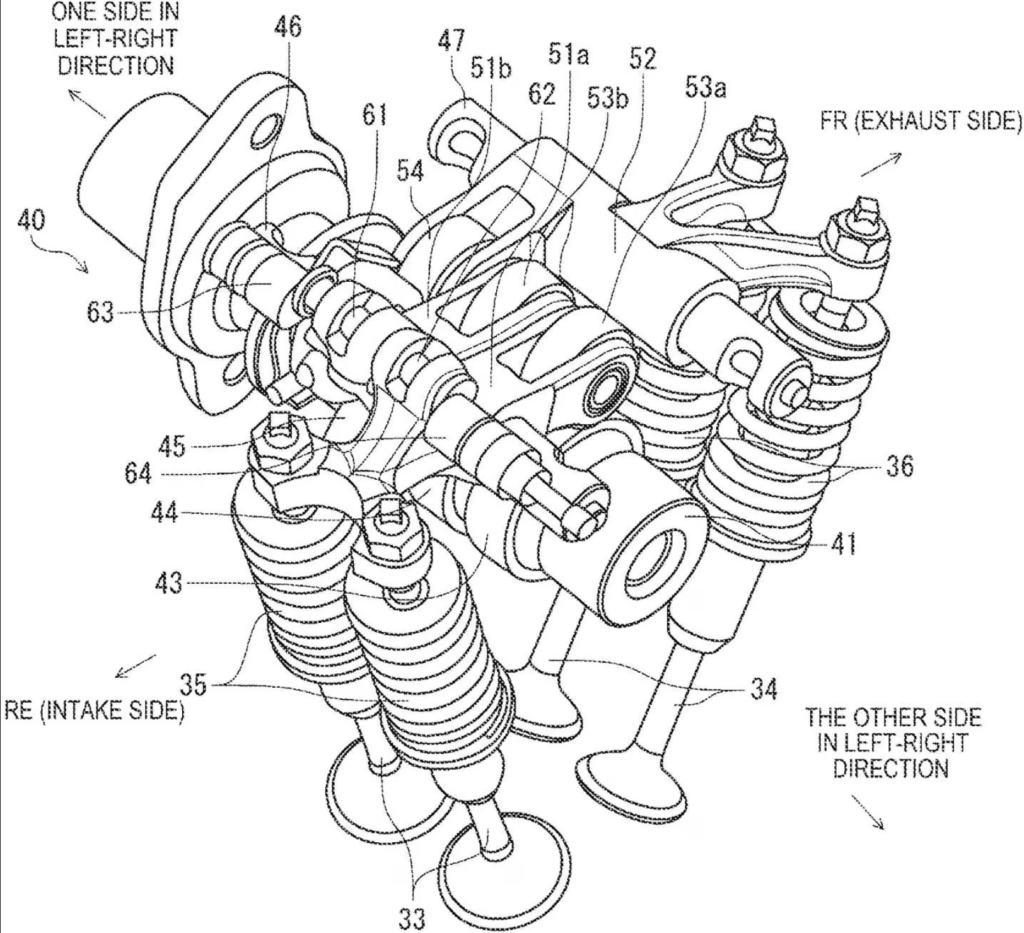

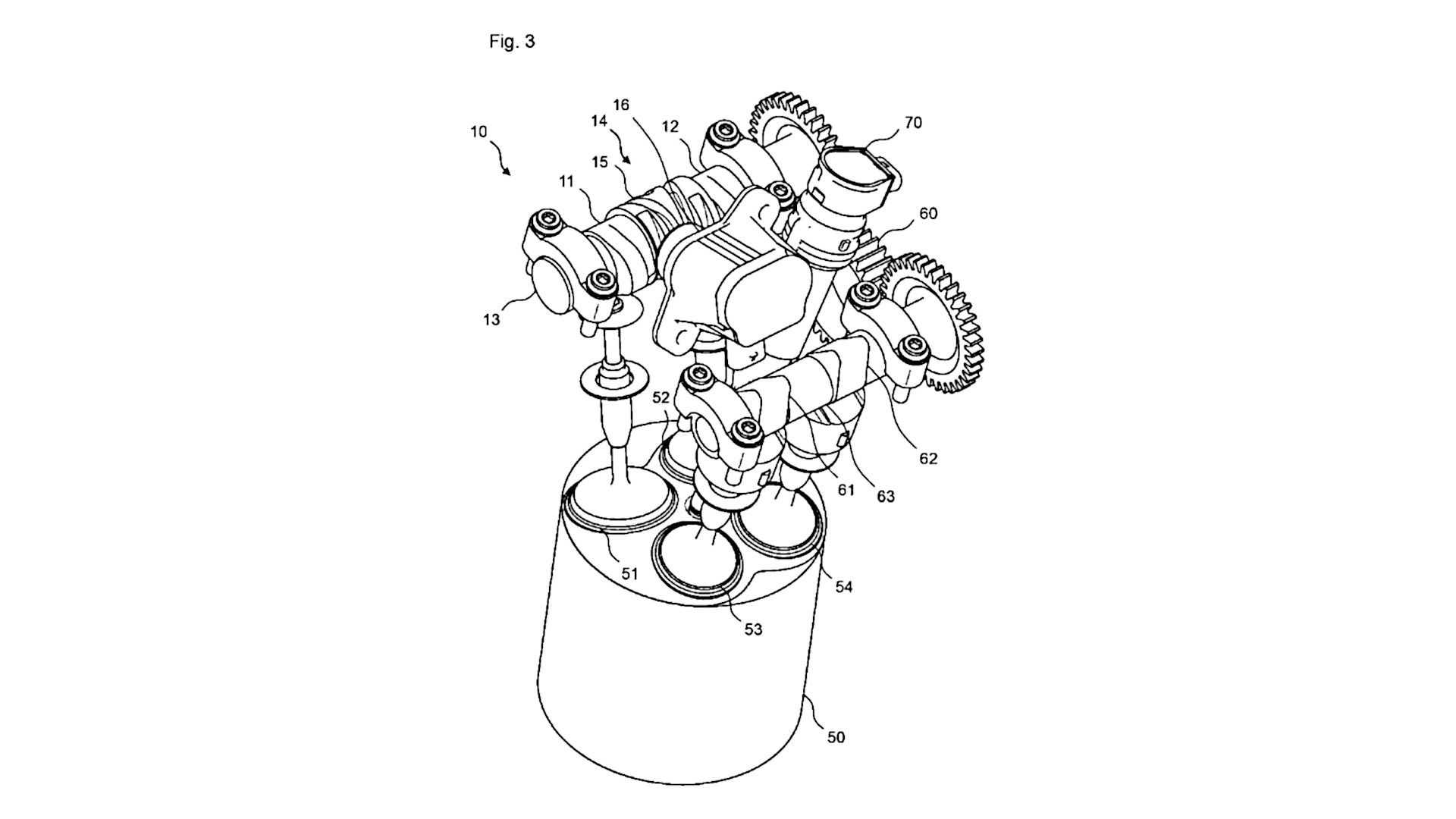

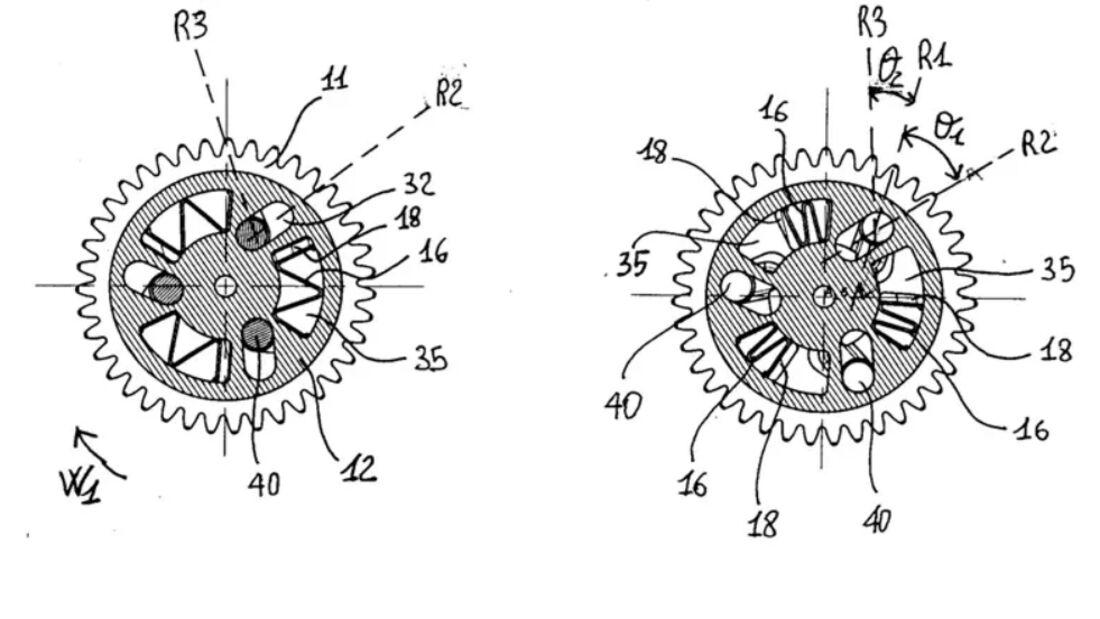

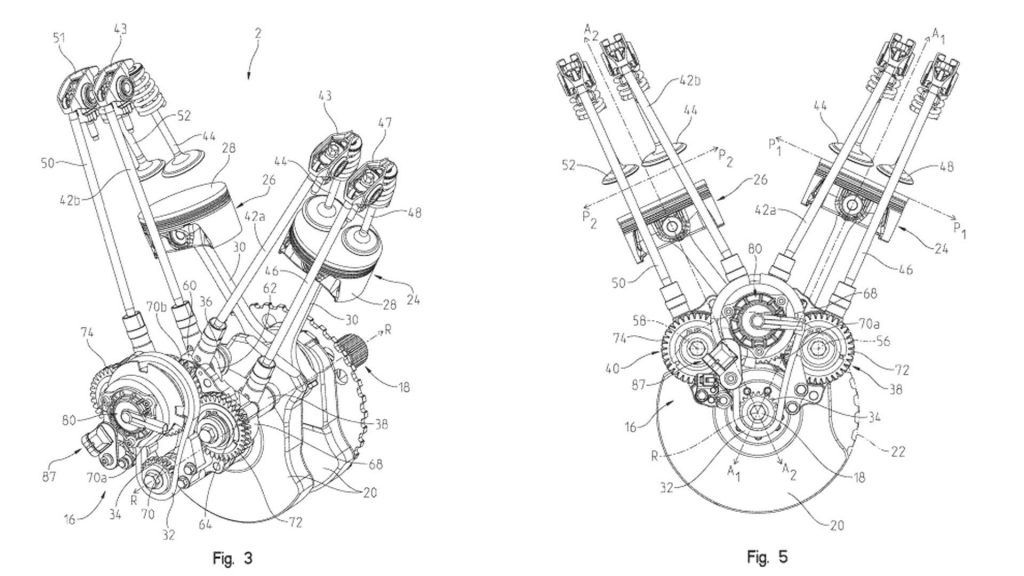

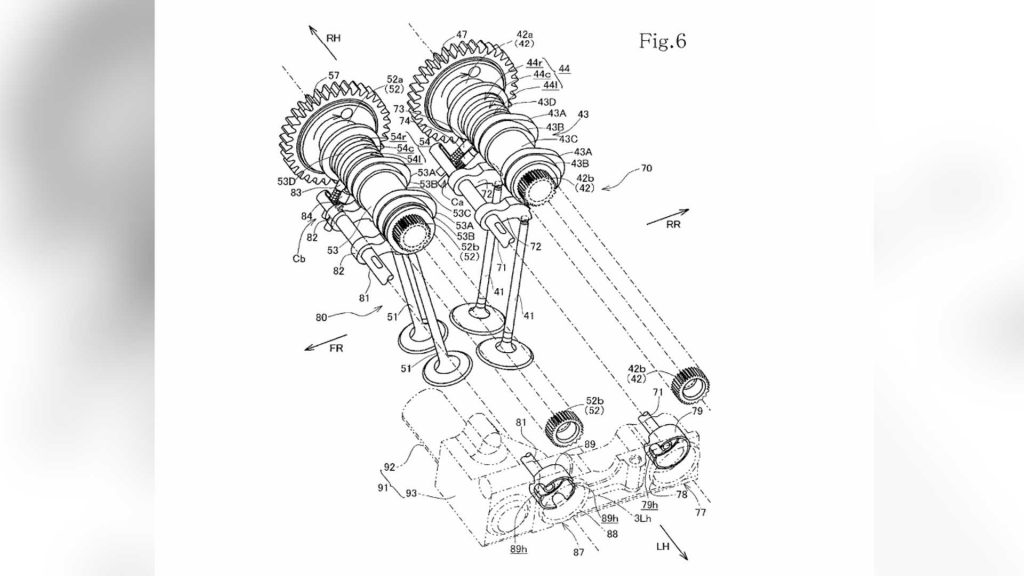

Suzuki’s system is basically similar to Yamaha’s VVA (Variable Valve Actuation) used on the NVX scooter, Y16ZR moped, and YZF-R15. It uses a camshaft with two cam lobe profiles, one for normal low end, low demand application, while locking on a higher lift and longer duration cam lobe at high speeds or big throttle openings.

As such, it is the best of both worlds: Good low and midrange RPM torque with high maximum power. Engineers have to pick one characteristic: low RPM torque, midrange torque, or high end horsepower without VVT and VVL. Using VVT also allows the engine to produce cleaner emissions as it cuts down on unburned fuel.

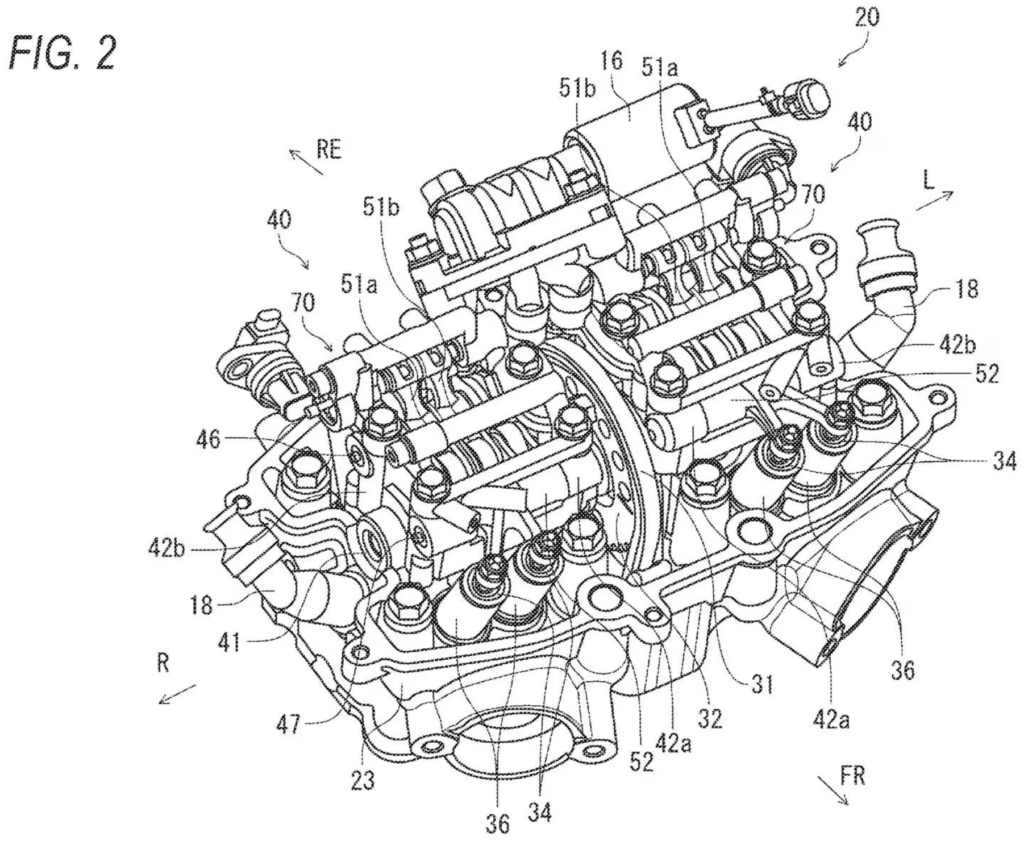

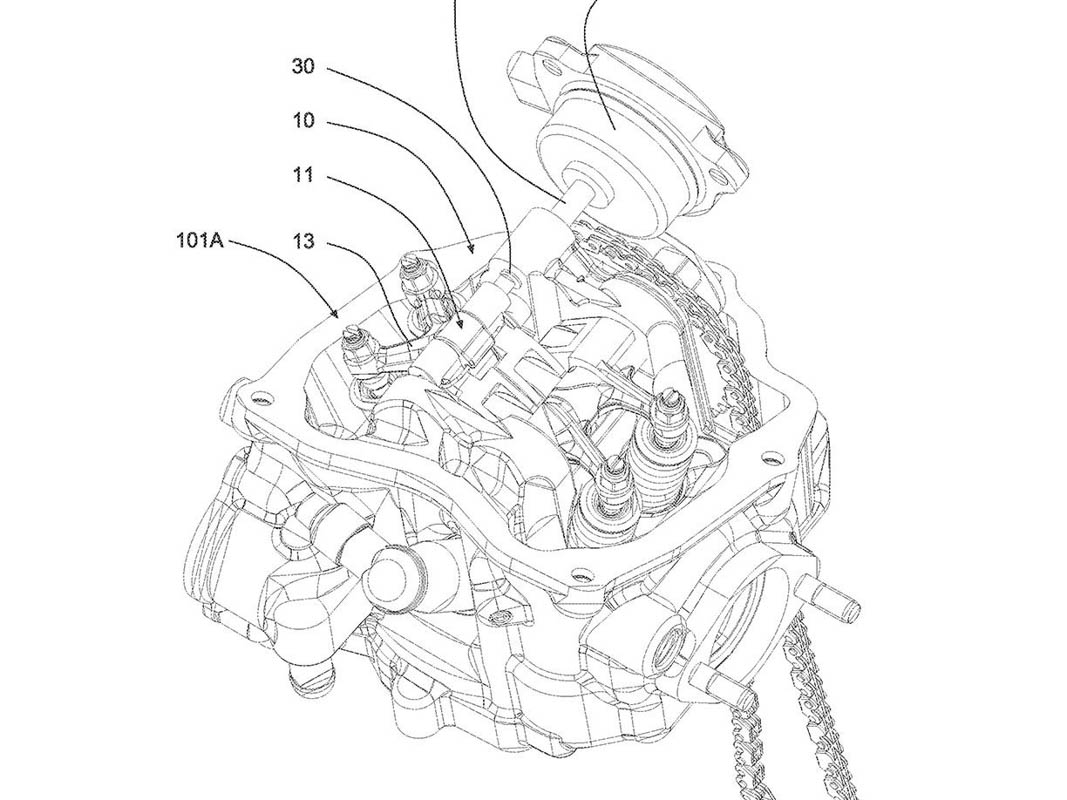

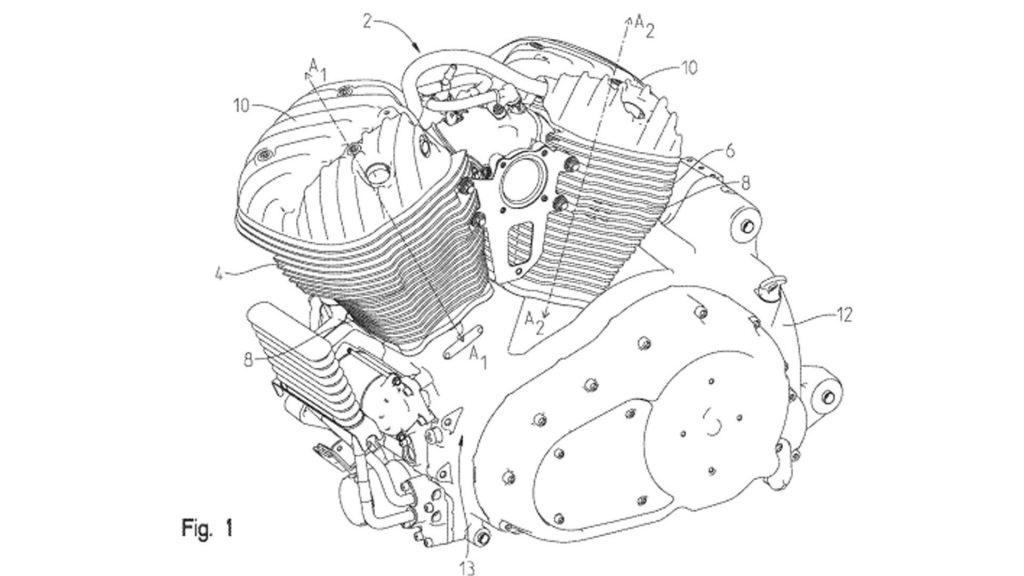

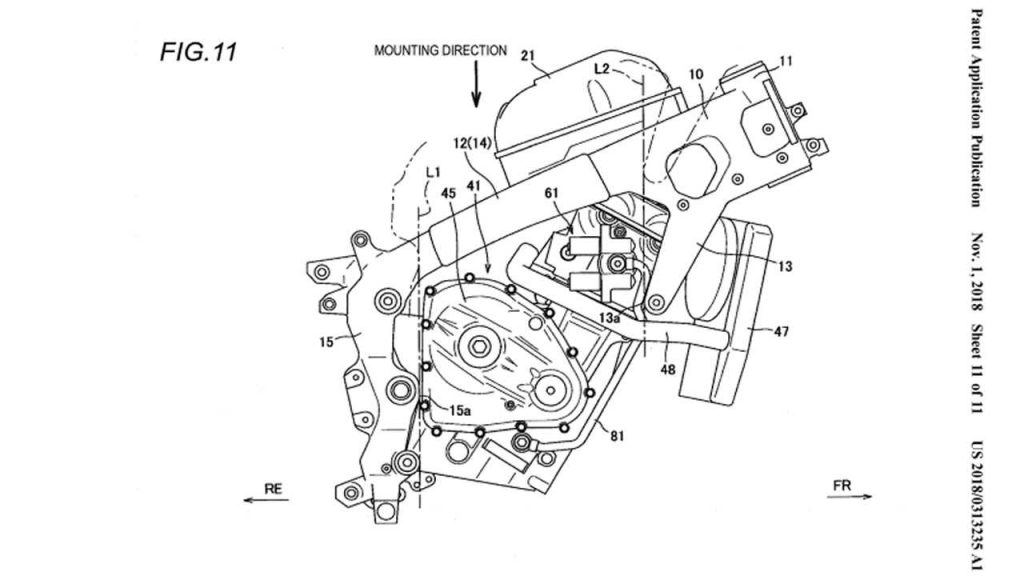

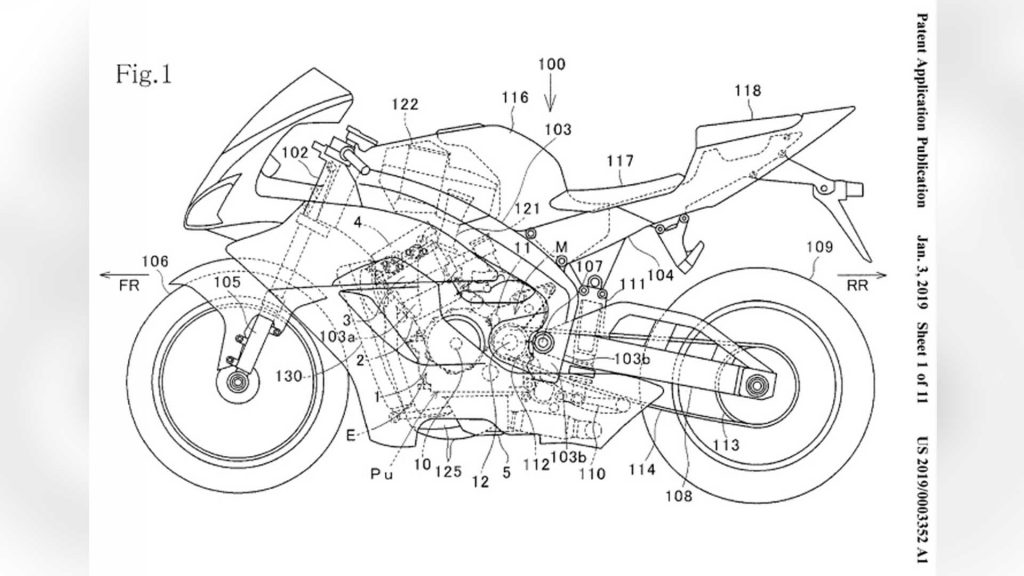

As aforementioned, Suzuki’s development centres around the parallel-twin 248cc engine. Patent applications show an engine with an unchanged bottom end, a cylinder head with a single camshaft driven by a centrally mounted chain. It is the same engine used on the GSX-250R and V-Strom 250.

The same engine, enlarged to 298cc is also in use by Suzuki’s partner Haojue in China. Haojue is the firm responsible for producing the V-Strom 250 and GSX-250R.

Suzuki current does not have any models in between GSX-R125 and 650cc models (V-Strom 650, SV650) in the United States due to emissions control, so a range of 250cc bikes with VVT will fix that.